Electric vehicles are here, and they are essential for decarbonizing transport. The United Kingdom, California, the European Union, Canada and others plan to phase out the sale of fossil-fuelled vehicles as early as 2030 — Norway plans to do it sooner. Consumers are interested. In May, the Ford Motor Company unveiled an all-electric version of its best-selling pick-up truck, the F-150 Lightning. By August, so many customers had reserved one that Ford doubled its initial production target. On 27 September, the company announced that it will spend billions of dollars to build battery factories and an electric-truck plant in the United States. Other companies are expanding their production, too.

Major investments in electric vehicles are welcome news. The sector has come a long way, but many challenges lie ahead. One issue that has received too little attention, in our view, is the increasing weight of vehicles. Pick-up trucks and sport utility vehicles (SUVs) now account for 57% of US sales, compared with 30% in 1990. The mass of a new vehicle sold in the United States has also risen — cars, SUVs and pick-up trucks have gained 12% (173 kilograms), 7% (136 kg) and 32% (573 kg), respectively, since 1990. That’s equivalent to hauling around a grand piano and pianist. Similar trends are seen elsewhere in the world.

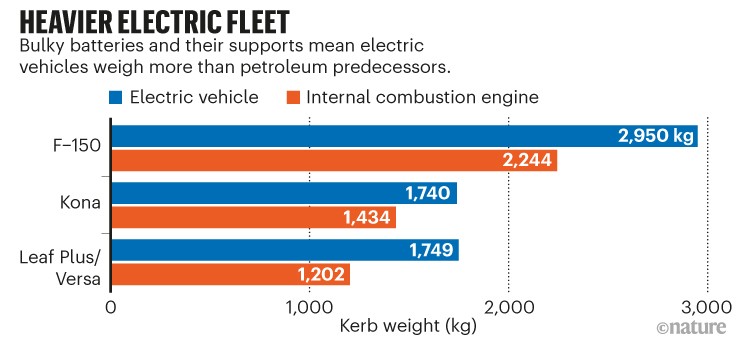

Electrifying vehicles adds yet more weight. Combustible, energy-dense petroleum is replaced by bulky batteries. And the rest of the vehicle must get heavier to provide the necessary structural support1. The electric F-150 weighs 700 kg more than its petrol-powered predecessor. Smaller electric cars are heavier than their petrol equivalents, too (see ‘Heavier electric fleet’).

Why does this matter? First and foremost is safety. The likelihood of passengers being killed in a collision with another vehicle increases by 12% for every 500-kg difference between vehicles2. This added risk wouldn’t apply if everyone drove cars of similar heft. But until they do, the number of casualties in crashes is likely to increase as heavy electric vehicles join lighter existing fleets. Pedestrians will also be at risk. If US residents who switched to SUVs over the past 20 years had stuck with smaller cars, more than 1,000 pedestrian deaths might have been averted, according to one study3.

Heavier vehicles also generate more particulate pollution from tyre wear. They require more materials and energy to build and propel them, adding to emissions and energy use.

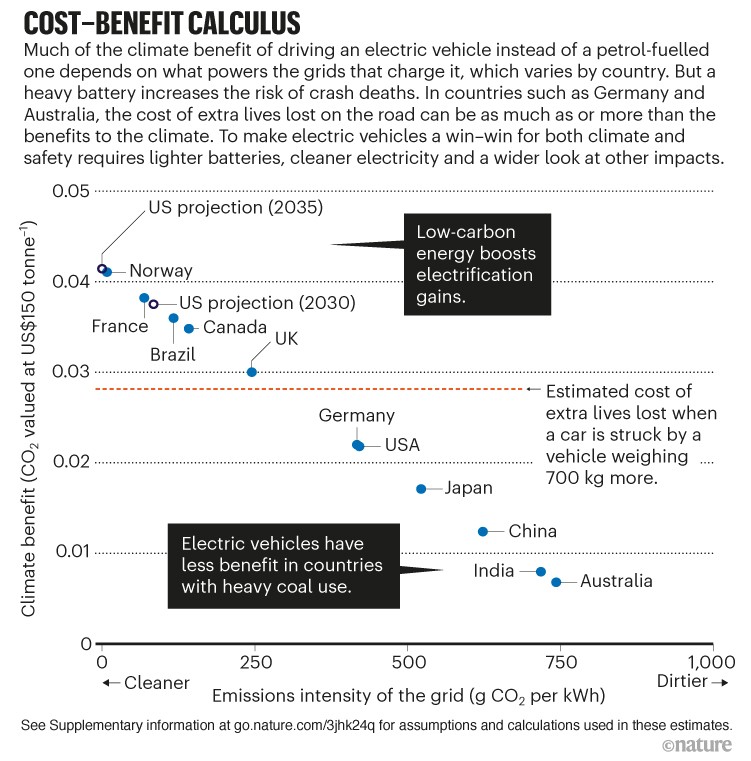

How big a problem is this extra weight? A rough comparison between mortality costs and climate benefits shows that it is significant. Under the energy systems operating in most countries today, the cost of extra lives lost from a 700-kg increase in the weight of an electrified truck rivals the climate benefits of avoided greenhouse-gas emissions.

Two main factors are at play: the battery’s weight and supports as well as the cleanliness of the electricity grids it is charged from. In calculating the cost of the extra weight, we used the US Department of Transport’s value of US$11.6 million per avoided fatality. The cost–benefit trade-off holds even if we assume that the social cost of emitting one tonne of carbon dioxide is high, around $150; lower values, such as $50, reduce the estimates for climate benefits. Admittedly, it’s an oversimplification. Realistic cost–benefit analyses for electric vehicles require the evaluation of many other factors. These include the costs from injuries in collisions, the health benefits from cleaner air and the life-cycle impacts of different car designs.

As time goes on, cleaner grids will strengthen the case for electric vehicles. Some countries with lots of clean electricity sources, such as Norway, are already at a point at which electrifying a truck has more climate benefits than safety costs. Others, including the United States, must keep on the path to net-zero electricity systems (see ‘Cost–benefit calculus’). Yet without addressing the weight issue, the benefits for society of going electric will be smaller than they could be in the next decade. Here’s what we think researchers, policymakers and manufacturers need to do to address the issue.

Tax heavy cars

Basic economics tells us that activities that impose costs on others should be taxed. Setting registration charges on the basis of vehicle weight can discourage heavy vehicles and encourage light ones. Collecting weight-based charges also addresses another looming problem for governments — lost revenue from forgone petrol and diesel taxes as more electric vehicles hit the roads.

That’s potentially a lot of money. In 2019, US federal, state and local governments collected more than $112 billion in fuel taxes. Several states have already started levying fees on electric-vehicle owners, in the range of $50–200 per year, to recoup some of that lost tax. It’s fair, they argue, because fuel taxes cover part of the costs of road infrastructure, which electric-vehicle drivers use, too.

Varying such charges by weight would maintain revenue while incentivizing people to choose vehicles that are more energy efficient and impose fewer social costs4. It would also reduce other emissions from materials production and manufacturing.

A few places have such taxes. In Iowa, for example, the registration fee increases by $0.40 for every 45 kg of vehicle weight. In New York state, the rate is $1.50 per 45 kg for weights above 750 kg; above 1,600 kg, it rises to $2.50. France will go even further next year, charging a whopping €10 (US$11.60) for every kg that exceeds an 1,800 kg threshold. If that law didn’t already exempt electric and hybrid vehicles, it would have added €12,000 to the price of an electric truck, such as the F-150.

Adding travel distance to the fee would also incentivize people to drive less. Oregon is piloting such a programme, giving owners the option to base their registration fees on the distance they drive in a year (at a rate of roughly 1.1 cents per kilometre) in lieu of fixed annual fees. Travel data can be collected by on-board devices; some insurance companies already offer policies that are based on total mileage and other driving habits.

Shrink batteries

Batteries now cost 90% less than they did ten years ago. And their energy density has more than tripled5 since lithium-ion batteries were introduced in 1991. Yet most of the gains in battery technology have gone to increase the distance an electric car can travel in a single charge, and to boost the car’s power. Over the past decade, for example, Nissan has brought to market a long-range version of its flagship Leaf electrical vehicle, with triple the range (364 kilometres) and double the horsepower (214 hp). But its weight has grown, too, by 14%, to 1,749 kg.

Driving range is important for the widespread adoption of electric vehicles. Most consumers buy cars on the basis of reach because they worry about losing power or being unable to recharge on a long trip. Yet, most car journeys are short — to the shops or school. In the United States, for example, on average, drivers travel 56 kilometres per day, far short of the maximum range for electric vehicles.

Extending that reach by another 100 kilometres or so every few years will make electric vehicles more practical for people who need to travel long distances regularly, for work for example. But even now, it has diminishing returns for the average driver. Fast-charging infrastructure is being deployed more widely. Producing lightweight batteries will reap rewards immediately.

Ways to lighten batteries include using materials that are more energy-dense, and removing heavier components. For example, solid-state batteries that don’t use liquid electrolytes and have the latest anode chemistries are more compact and could offer higher energy densities than is possible for lithium-ion cells. Lithium–silicon batteries can achieve higher energy densities if manufacturers use more silicon in anodes rather than graphite. Improvements can also be digital — wireless battery management systems can shed up to 90% of the web of wires. Using fewer materials helps manufacturers to save money.

But cutting-edge technologies are expensive to incorporate, raising the costs of electric cars. Government support, from the laboratory to the factory to the consumer, is thus essential to spur innovation and development. Weight-based registration charges could supply some of that money. US subsidies for electric vehicles currently increase with the storage capacity of the battery. Basing electric-vehicle subsidies instead on energy storage per kg (kWh kg−1) would incentivize advances in lighter batteries.

Further developments in battery technology are needed to reduce pollution from manufacturing and to consume less cobalt and other rare metals and minerals. Schemes for recycling and reusing battery and other materials need to be put in place6, before tens of millions of electric vehicles arrive on and then leave the roads.

Lighten frames

Tesla, Volvo, GM and other car makers are exploring using battery packaging to support part of the vehicle’s chassis. On the horizon is making the vehicle frame itself the medium to store energy. Research and development is needed to improve conductivity, strength and how structural batteries handle crashes7.

About one-third of a vehicle’s mass is conventional steel, down from 44% in 1995. Vehicle structures can be made stronger and lighter by using advanced forms of steel, more aluminium and magnesium, and polymers reinforced with carbon fibre. Each material brings its own cost and technical challenges as well as emissions impacts from production and supply chains. Researchers need to assess these trade-offs to find safe, clean and affordable solutions.

Substituting aluminium for steel reduces vehicle weight and improves energy efficiency. But aluminium production can have nearly five times the embodied carbon emissions of steel8. Switching to recycled aluminium with a low-carbon grid can lower life-cycle emissions to below those of steel.

Reduce crashes

With heavier vehicles on the road, safety becomes even more important. Some vehicles already use cameras, radar and other sensors to avoid collisions by monitoring blind spots and driver alertness. These devices keep vehicles in lanes, adjust speeds, control headlights and apply the brakes if there’s a threat of a crash. Deploying such technologies across the entire US vehicle fleet could avoid thousands of fatalities, more than one million crashes and billions of dollars in social costs annually9.

Old ideas to improve street safety should still be encouraged — speed limits, traffic calming road designs and pedestrian-focused infrastructure. Paris, Brussels, Bilbao and other cities have limited speeds on most roads to 30 kilometres per hour.

Drive less

Reducing the distance driven can help in meeting climate targets as electric and, eventually, automated vehicles become widely available10. Policies should ensure that alternatives such as walking, biking and public transport are safer, more convenient, accessible, affordable and reliable.

Urban designers should consider the impacts of zoning and development on driving patterns to minimize average distances travelled and air-pollution impacts that disproportionately burden vulnerable communities. One legacy of the COVID-19 pandemic is a realization of how much work can be done remotely, with less commuting. Solving these challenges will save lives and protect the climate.

Ultimately, to manage climate change, the world needs to stop emitting greenhouse gases from vehicles and power plants. Electric vehicles powered from a clean grid are an essential step in the right direction. A focus on driving lighter, safer, cleaner and less can ensure a better future for everyone.